Monolithics

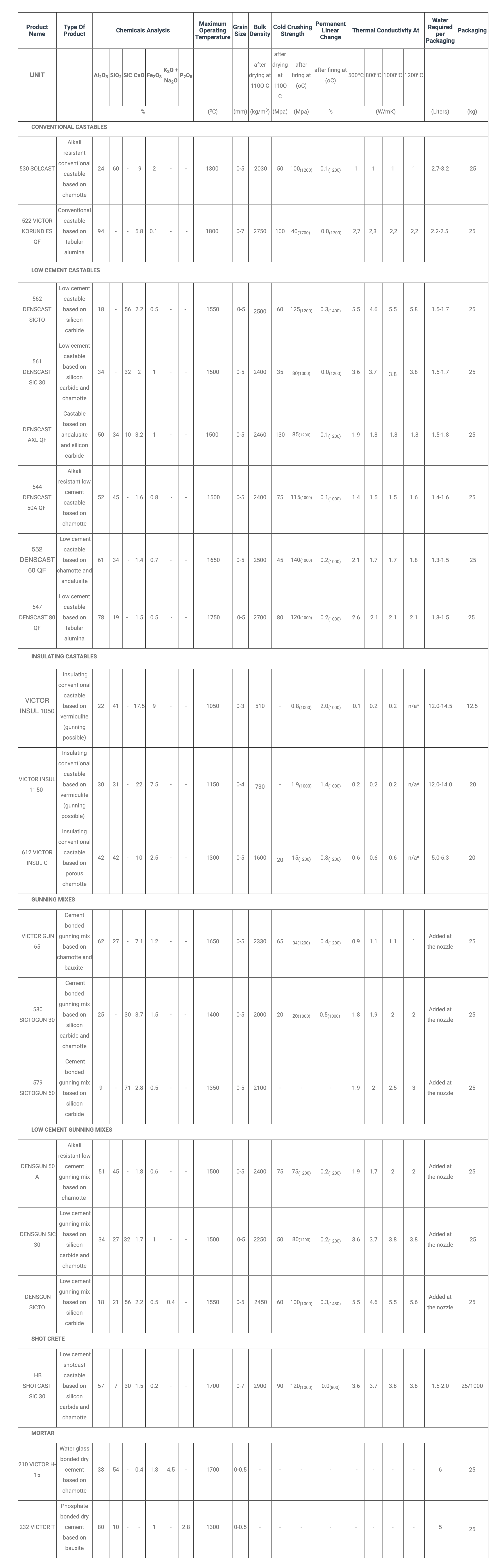

There is a wide range of refractory castables, grouped as follows:

Conventional castables, normally with 15-25% binding cement, are easy to mix. Their setting time is 1-4 hours, and they have medium strength.

Low-Cement castables (LCC) usually have only 4-6% binder (cement and chemical), and require careful mixing in a paddle mixer, with accurate proportioning of water and vibration to assure their proper settling. Their setting time is usually 3-4 hours.

Self-floating castables are a sub-category of LCCs, but contain an additive that makes it unnecessary to vibrate. These are not recommended for field work.

Non-cement castables normally contain > 1% binder. Their setting time exceeds 5 hours, and they are difficult to mix. They are not recommended for use outside controlled environments.

Gunnables

All conventional refractory castables are also available as gunnables.

LCC castables can be gunned, if special equipment is employed. Please contact your HöganäsBjuf representative for more information.

Some castable products are also available as moldables. These wet blocks can be rammed with pneumatic hammers to conduct local repairs without the need of a casting mold. Again, please contact your HöganäsBjuf representative for more information.

Mortar and Cement

Cement or mortar is used to join bricks. Cements harden at room temperature, while mortars normally require a temperature of at least 300 degrees before they are properly cured.

Conventional castables, normally with 15-25% binding cement, are easy to mix. Their setting time is 1-4 hours, and they have medium strength.

Low-Cement castables (LCC) usually have only 4-6% binder (cement and chemical), and require careful mixing in a paddle mixer, with accurate proportioning of water and vibration to assure their proper settling. Their setting time is usually 3-4 hours.

Self-floating castables are a sub-category of LCCs, but contain an additive that makes it unnecessary to vibrate. These are not recommended for field work.

Non-cement castables normally contain > 1% binder. Their setting time exceeds 5 hours, and they are difficult to mix. They are not recommended for use outside controlled environments.

Gunnables

All conventional refractory castables are also available as gunnables.

LCC castables can be gunned, if special equipment is employed. Please contact your HöganäsBjuf representative for more information.

Some castable products are also available as moldables. These wet blocks can be rammed with pneumatic hammers to conduct local repairs without the need of a casting mold. Again, please contact your HöganäsBjuf representative for more information.

Mortar and Cement

Cement or mortar is used to join bricks. Cements harden at room temperature, while mortars normally require a temperature of at least 300 degrees before they are properly cured.