Fire Clay and High Alumina Bricks

The oxides of silicon and aluminum form the basis of fire clay and high alumina bricks.

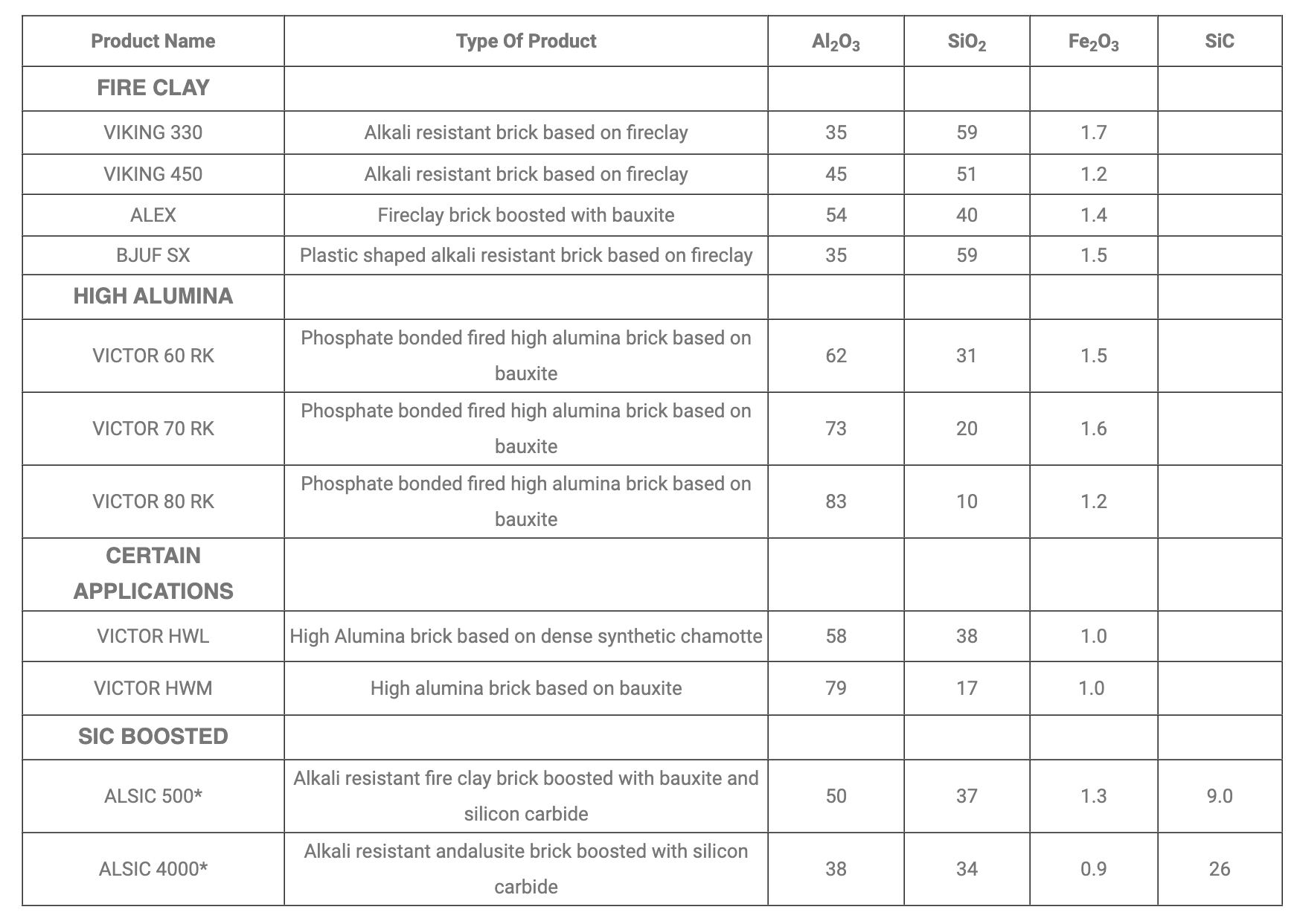

Fireclay Clay Bricks

The composition of fireclay bricks are in the SiO2-Al2O3 system, with 5-80% SiO2 and between 20-45% Al2O3. HöganäsBjuf’s vast experience and own raw material deposits ensures top performance and quality. For areas of application please look into the process.

High Alumina Bricks

According to the description above of fireclay bricks, the High Alumina Bricks belong to the SiO2-Al2O3 system.

The definition of High Alumina is that it has a Al2O3 content above 45%. The higher alumina content normally gives better refractoriness at higher temperatures in comparison with Fireclay Bricks.

Cement and Mortar

Cement or mortar is often used to join bricks. Cements harden at room temperature, while mortars normally require a temperature of at least 300 degrees before they are properly cured

Fireclay Clay Bricks

The composition of fireclay bricks are in the SiO2-Al2O3 system, with 5-80% SiO2 and between 20-45% Al2O3. HöganäsBjuf’s vast experience and own raw material deposits ensures top performance and quality. For areas of application please look into the process.

High Alumina Bricks

According to the description above of fireclay bricks, the High Alumina Bricks belong to the SiO2-Al2O3 system.

The definition of High Alumina is that it has a Al2O3 content above 45%. The higher alumina content normally gives better refractoriness at higher temperatures in comparison with Fireclay Bricks.

Cement and Mortar

Cement or mortar is often used to join bricks. Cements harden at room temperature, while mortars normally require a temperature of at least 300 degrees before they are properly cured